Each year, many thousands of tons of forages – grass, maize, Lucerne, Whole Crop – are harvested and put up into bunkers, clamps and piles for silage. A crop of ensiled forage represents a sizable investment in time and money for livestock farms as it’s being stored for future use.

In many cases that forage was chopped and packed correctly, but still, many thousands of tons are spoiled and wasted due to exposure to air and improper feedout and face management. It’s not uncommon for a pile of silage to lose 15 percent or more of its total dry matter due to spoilage and volatilization of organic matter. This is a significant monetary loss particularly for dairy farms as the more forage that is lost the more purchased feeds required to fulfil the ration.

Air is not a friend to silage. When silage is exposed to air, a cascade of events result in aerobic spoilage:

• Yeasts “wake up” and degrade the lactic acid that originally stabilised the organic matter.

• As the population of yeasts increase, the more soluble nutrients such as sugars and proteins are destroyed.

• Heat is produced, leading to further degradation of organic matter.

• The pH (alkalinity) increases, leading to the growth of moulds and bacteria, causing additional spoilage.

Yeasts are the primary spoilers of silages and are abundant in the environment. One species of yeast in particular thrives on lactic acid, the primary acid found in properly fermented silage. These yeasts utilise the lactic acid for their own needs, releasing water and carbon dioxide as byproducts.

The CO2 removes carbon atoms – and therefore organic matter – and as these yeasts proliferate in silage, the organic matter literally vanishes into thin air. Other species of yeast will ferment sugars, again releasing CO2 along with ethanol, resulting in the additional loss of dry matter.

Faces of silage clamps exposed for extended periods of time will have the pH levels climb as the lactic acid is used up, providing an environment for moulds and bacteria that further degrades the quality of the organic matter.

It’s equally important to minimize any aerobic spoilage during harvesting and packing. Proper ensiling of forages requires the rapid production of lactic acid and lowering of the pH level. The sooner the ambient air in the pile is used up, the more quickly the fermentation is accomplished and the pile is stabilized.

Minimizing air and spoilage in silages requires that the pile is:

• Packed quickly

• Packed tightly

• Sealed quickly with Oxygen Barrier film with sufficient weight

The single-most effective management tool in avoiding or reducing aerobic spoilage in all silages is limiting the amount of air either trapped in the pile as it ferments or penetrating the film once its ensiled, as well as the amount of air penetrating the face of a clamp or silo as the silage is being fed out.

Even though exposure of the silage to air during the feeding process is inevitable and unavoidable, the key to reducing aerobic instability is to manage the face or silo in such a way as to minimize the exposed volume or square footage to as little as possible on a daily basis.

Although you can stop air ingress into the pile or bunker with an OB film air can penetrate into the face of even a well-packed silo as much as 3 feet. Removing only 6 inches of silage per day from a face means that the silage on the face today has been exposed to air for six days. Six days is plenty of time for yeasts to establish and begin degrading organic matter.

Removing 12 inches per day results in silage at the face being exposed to air for only three days. It’s impossible to completely eliminate a minimal amount of aerobic spoilage when feeding out a pile or silo of silage. The key is to remove enough silage daily to reduce the hours silage is exposed to air, minimizing the time for yeast growth.

Silage clamp sand bunkers should be sized and managed in such a way that at least 12 inches of feed can be removed per day, thus reducing the amount of “air time” penetrating the face. Large silage piles with “too many faces” sectioned off or divided into separate piles should be avoided.

Exposing large faces for many months at a time will result in loss of many thousands of pounds of silage to spoilage. During hot weather more silage must be removed since higher temperatures accelerate the spoilage process.

Recommended management for limiting aerobic spoilage include:

• Keep the face of a pile smooth with the use of a mechanical facer or other equipment.

• Avoid gouging and leaving uneven surfaces with front-end loaders.

• Knock down only enough silage to be used for the day.

• Avoid creating shelves and ledges.

• Avoid transporting and re-piling silage at a different location.

• Remove more silage per day from the face during hot weather or on poorly packed piles.

While proactive management of silage is the most effective way of avoiding aerobic spoilage, additives such as bacterial inoculants and organic acids, when properly applied, can help mitigate spoilage.

Maintaining aerobic stability in silages is critical to limiting both dry matter losses in the silage as well as maintaining the nutritional components and palatability of those forages. However, it’s important to understand that a low pH and high levels of lactic acid alone will not prevent aerobic instability.

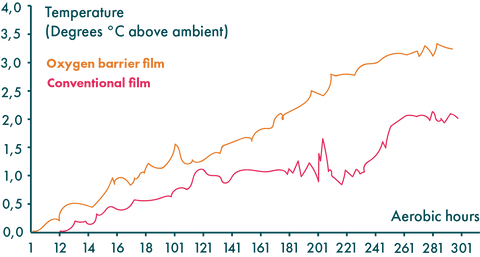

Trials carried out using Silostop OB films have shown that Aerobic stability can be prolonged by up to 2 1/2 days when compared to silage ensiled under standard PE films. This will significantly reduce the amount of spoilage and losses that can occur meaning much more silage can be fed to the cattle.

Average increase in stability = 2.5 days

Maintaining aerobic stability in silages is critical to limiting both dry matter losses in the silage as well as maintaining the nutritional components and palatability of those forages whilst minimising the growth of harmful bacteria and moulds which can be so detrimental to the cattle if eaten.